Screen Print:

2.Screen Design Guidelines 2

3.Screen Design Guidelines 3

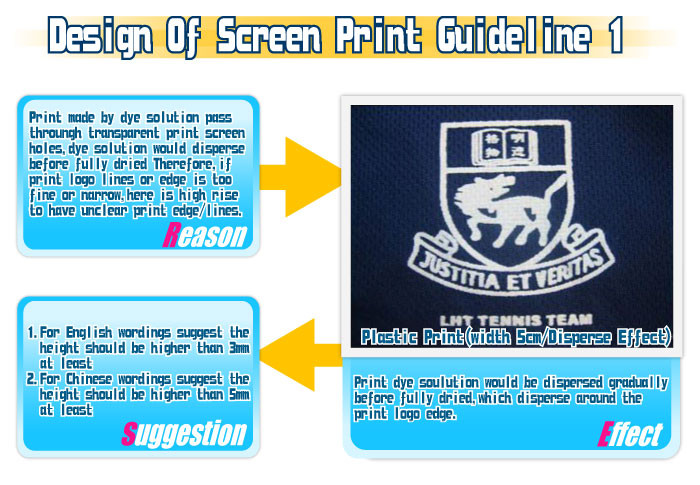

4.Screen print on colla

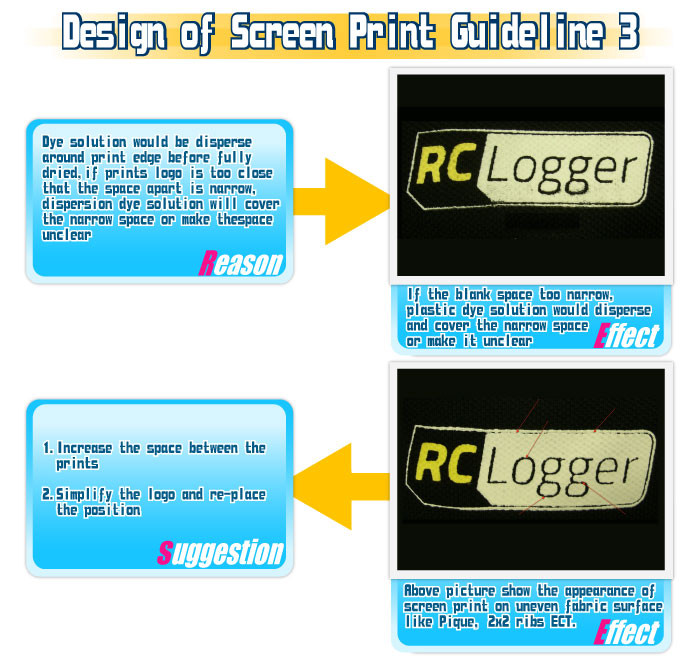

Design of Screen Print Guideline 1

Reason:

Print Made by dye solution pass thoungh transparent print screen holes,dye solution would disperse before fully dried Therefore,if print logo lines or edge is too fine or narrow,here is high rise to have unclear print edgge/lines.

Suggestion:

1:For English wordings suggest the height should be higher than 3mm at least

2:For Chinese wordings suggest the height should be higher than 5mm at least.

Effect:

Print dye soulution would be dispersed gradually before fully dried.which disperse around the print logo edge.

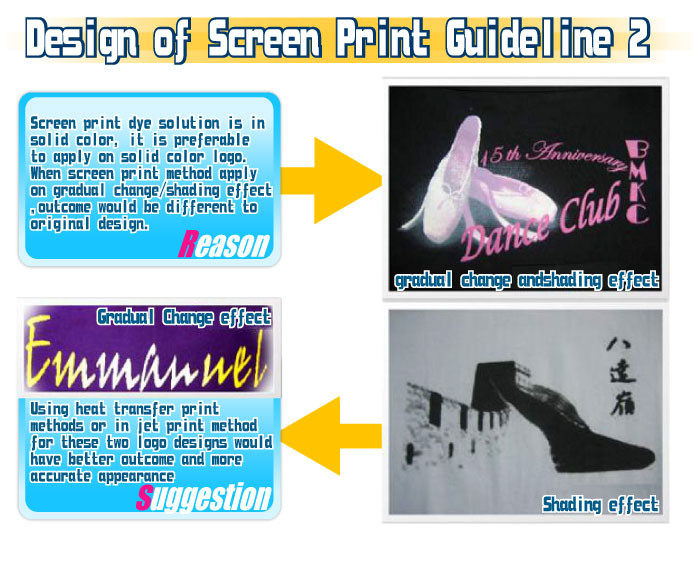

Design of Screen Print Guideline 2

Reason:

Screen print dye solution is in solid color,it is preferable to apply on solid color logo .When screen print method apply on gradual change/shading effect ,outcome would be different to original design.

Suggestion:

Using heat transfer print methods or in jet print method for these two logo designs would have better outcome and more accurate appearance

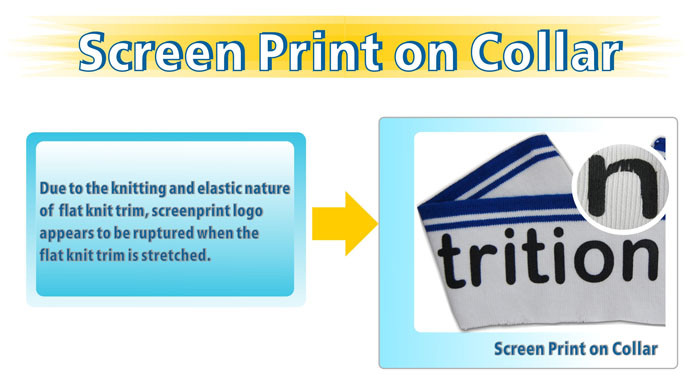

Design of screen print Guideline 3:

Reason:

Dye solution would be disperse around print logo is too close that the space apart is narrow .dispersion dye solution will cover the narrow space or make the space unclear.

Suggestion:

1:Increase the space between the prints

2:Simplify the logo and re-place the position

Effect:

If the blank space too narrow.Plastic dye solution would disperse and cover the narrow space or make it unclear.

Above picture show the appearance of screen print on uneven fabric surface like pique.2*2 ribs ECT.

Dragon Uniform provides a variety of screen printing select for our clients reference,Such as tee shirt printing, t shirts screen print, class tee screen printing or T-shirt print design and so on.